Products

With its expertise in the plastics industry, state of the art machinery, and a team of highly specialized professionals, it has today reached the highest level of technology.

Cooling Group Profiles

Cooling Group Profiles

From refrigerators, coolers, and industrial units to cooling towers, air conditioning, and plastic cooling profiles — our wide range of plastic extrusion cooling group profiles ensures fast response with uncompromising quality. With our extensive product portfolio, we hold the key to delivering the right solutions for your needs.

Plastic Price Tag Profiles

Plastic Price Tag Profiles

At Plastimak, our plastic extrusion label profiles represent the hidden effort behind every price tag. By focusing on clarity and transparency, we deliver price labels that are easy to read while making our craftsmanship visible. Behind what may seem simple at first glance lies a process of design, production, precision, testing, and quality control. Our success is built into the details — details you may not notice, but that make all the difference.

Polycarbonate Profiles

Polycarbonate Profiles

With our wide product range, extrusion polycarbonate profiles form our plastic lighting group. According to our customers’ needs, we manufacture with diffusers, transparent options, UV resistance, or in desired colors. In the design, production, and inspection stages of these polycarbonate profiles used in lighting systems, we focus not only on dimensional accuracy but also on light transmission to deliver the highest quality. Our primary goal is to continuously expand our polycarbonate product range and reach a broader customer portfolio.

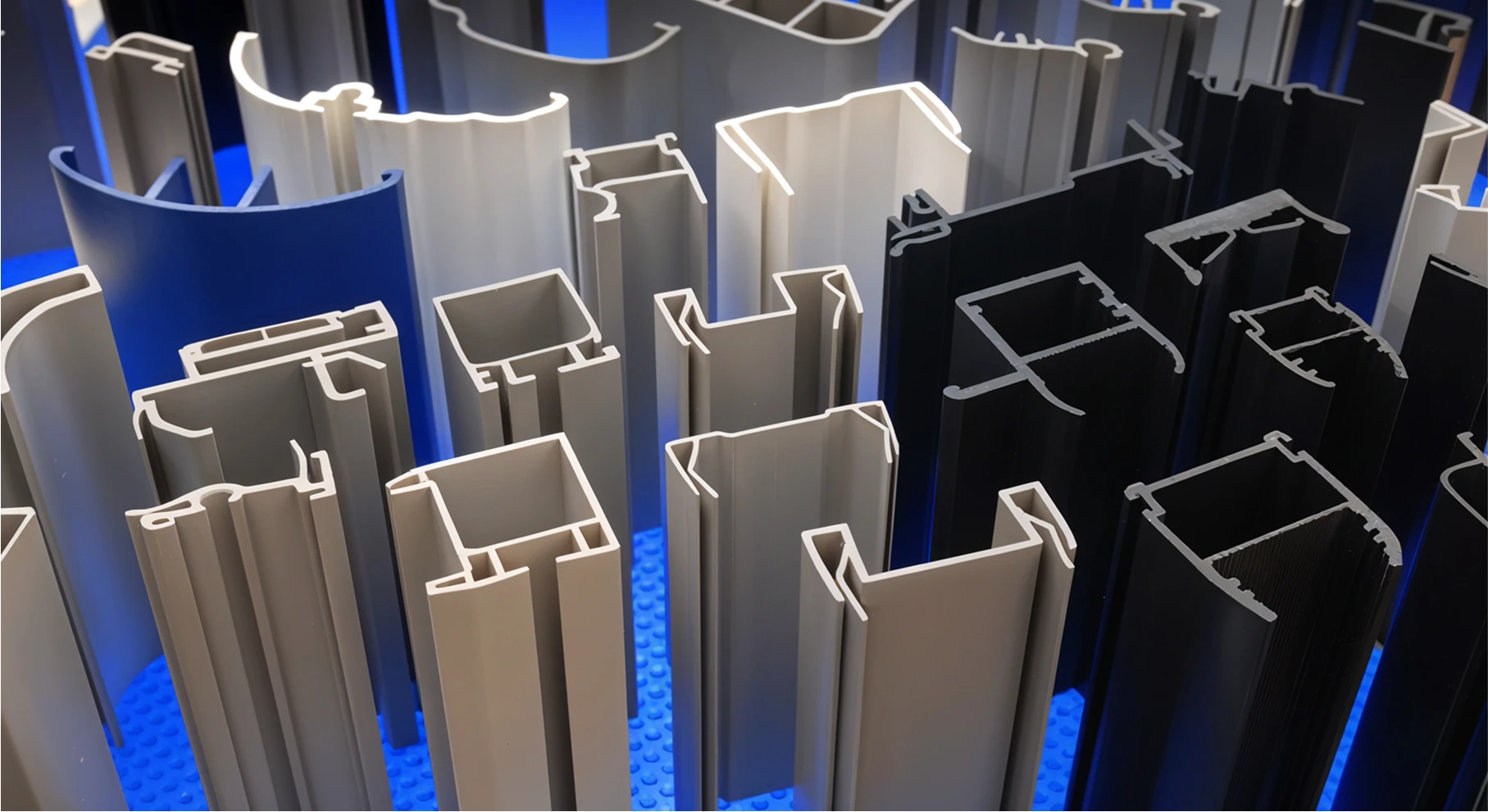

Aluminum System, Thermal Insulation, Thermal Barrier, and Box Profiles

Aluminum System, Thermal Insulation, Thermal Barrier, and Box Profiles

Our extensive product range includes plastic extrusion aluminum system profiles, which — thanks to advancing technology and cost efficiency — are increasingly replacing traditional aluminum profiles. We also offer plastic thermal insulation and thermal barrier profiles, widely used for joining aluminum systems and preventing heat transfer. In addition, our durable plastic box profiles, frequently applied in façade systems and many other applications, are produced with precision by our expert tooling team.

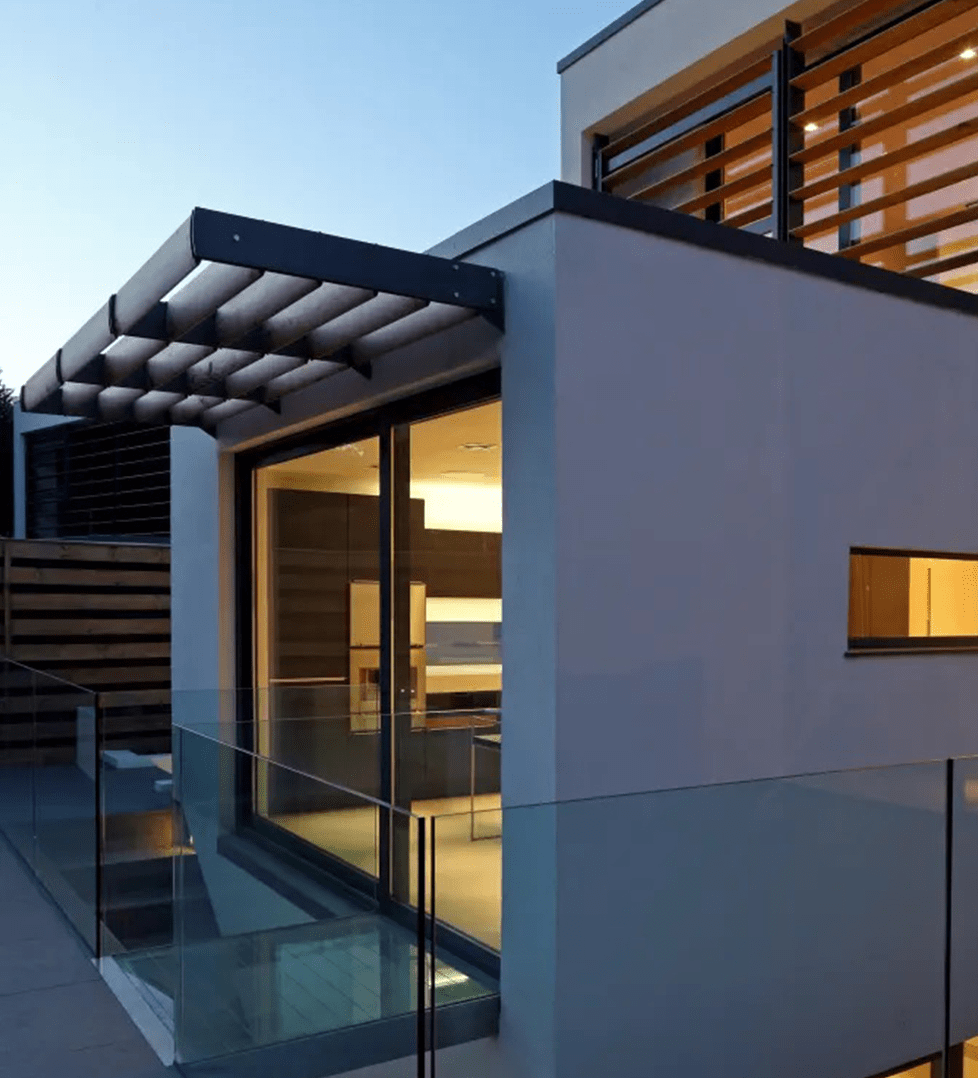

Plastic Shower Cabin, Glass Partition, and Magnetic Profiles

Plastic Shower Cabin, Glass Partition, and Magnetic Profiles

At Plastimak, we manufacture shower cabin, glass partition, and magnetic profiles to broaden our product diversity and provide you with more versatile solutions. Through advanced CO-EX and TRIPLE-EX production, our plastic shower cabin and glass partition profiles deliver enhanced softness, superior locking performance, and greater usability. The hardness of the flexible section is precisely engineered based on its application area. Our extrusion magnetic profiles the core of glass partition and shower cabin systems are designed to maintain their strength and ensure reliable performance in every open-close cycle.

Plastic Furniture, Skirting, Paneling, Corner, and T-Profiles

Plastic Furniture, Skirting, Paneling, Corner, and T-Profiles

Our product range includes a wide selection of plastic extrusion profiles such as furniture accessories, skirting boards, paneling, corner, and T-profiles — ensuring you’ll always find the right solution for your needs. Beyond our standard range, we also offer tailor-made designs, delivering the Plastimak difference with every detail. For us, your satisfaction is the driving force behind our work. That’s why aesthetics, durability, and functionality remain at the core of both our existing products and the custom solutions we create just for you.”

Plastic Boat, Stair, Handrail, Automotive, and Automatic Door Profiles

Plastic Boat, Stair, Handrail, Automotive, and Automatic Door Profiles

We also manufacture special profiles designed for areas exposed to high loads, such as boats, yachts, and stairs. Our handrail profiles are engineered to absorb applied loads and minimize potential damage to the application area. Plastic automatic door profiles, built with the same structure, are also produced for this purpose. Within our carefully manufactured range of plastic profiles, one group holds a particularly high importance for us: plastic automotive profiles. Just imagine how critical these can be for both us and our customers. Picture a plastic profile that combines high impact resistance, flexibility, and strong bonding properties that’s exactly what we deliver.

Plastic Custom Field Profiles

Plastic Custom Field Profiles

As the Plastimak family, we take pride in offering unlimited variety — proving that boundaries simply don’t exist for us. Here we present our special application profiles. While some profiles serve multiple purposes, others are designed exclusively for their intended application. Our productions for areas such as slides, aquariums, and pools make up our range of special application profiles.

Plastic Soft Profiles

Plastic Soft Profiles

Our soft profiles are made from a vinyl polymer available in various levels of softness, grades, and a wide range of colors. They are highly flexible and adaptable, with numerous additives for color, UV stabilization, and flame retardancy.

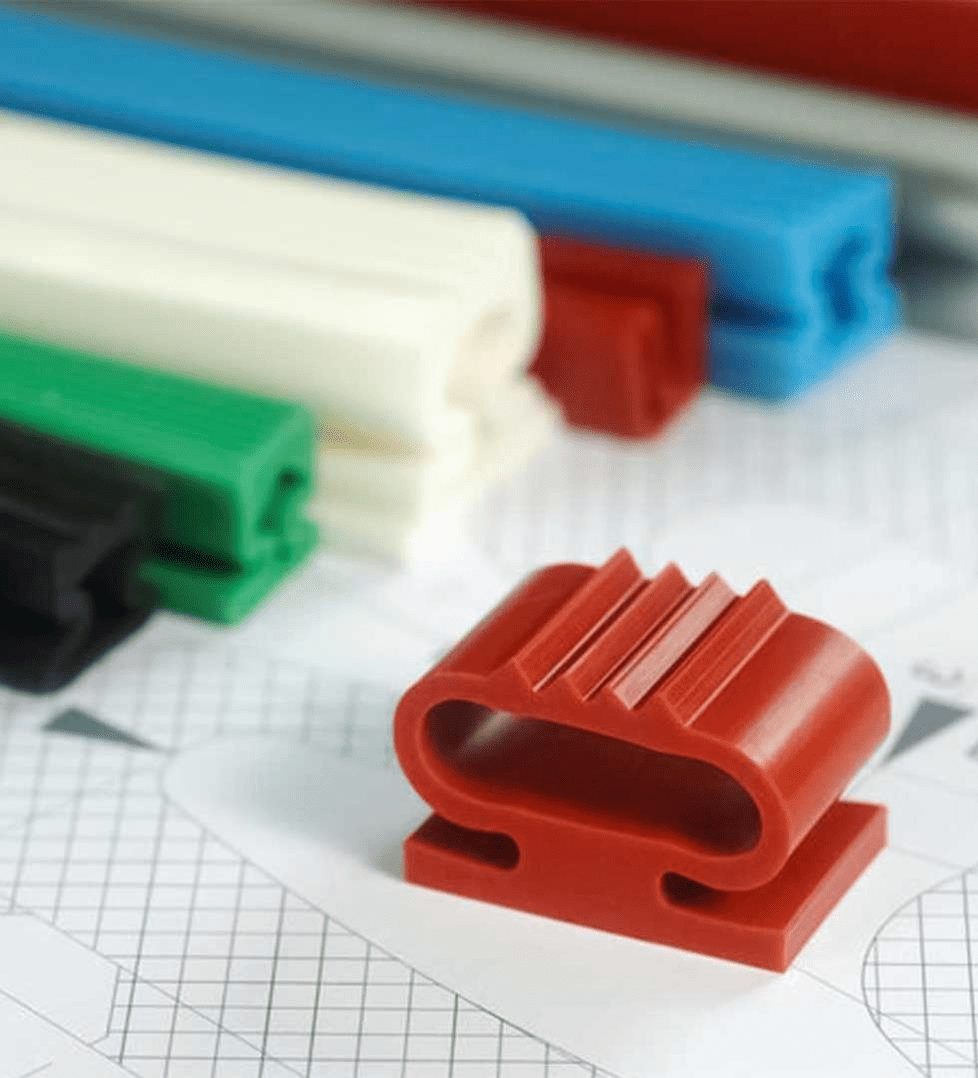

Plastic Injection Products

Plastic Injection Products

From sample mold design to post-production molding stages, we work closely with you throughout the entire process, carrying out plastic molding production with our state-of-the-art injection machines.